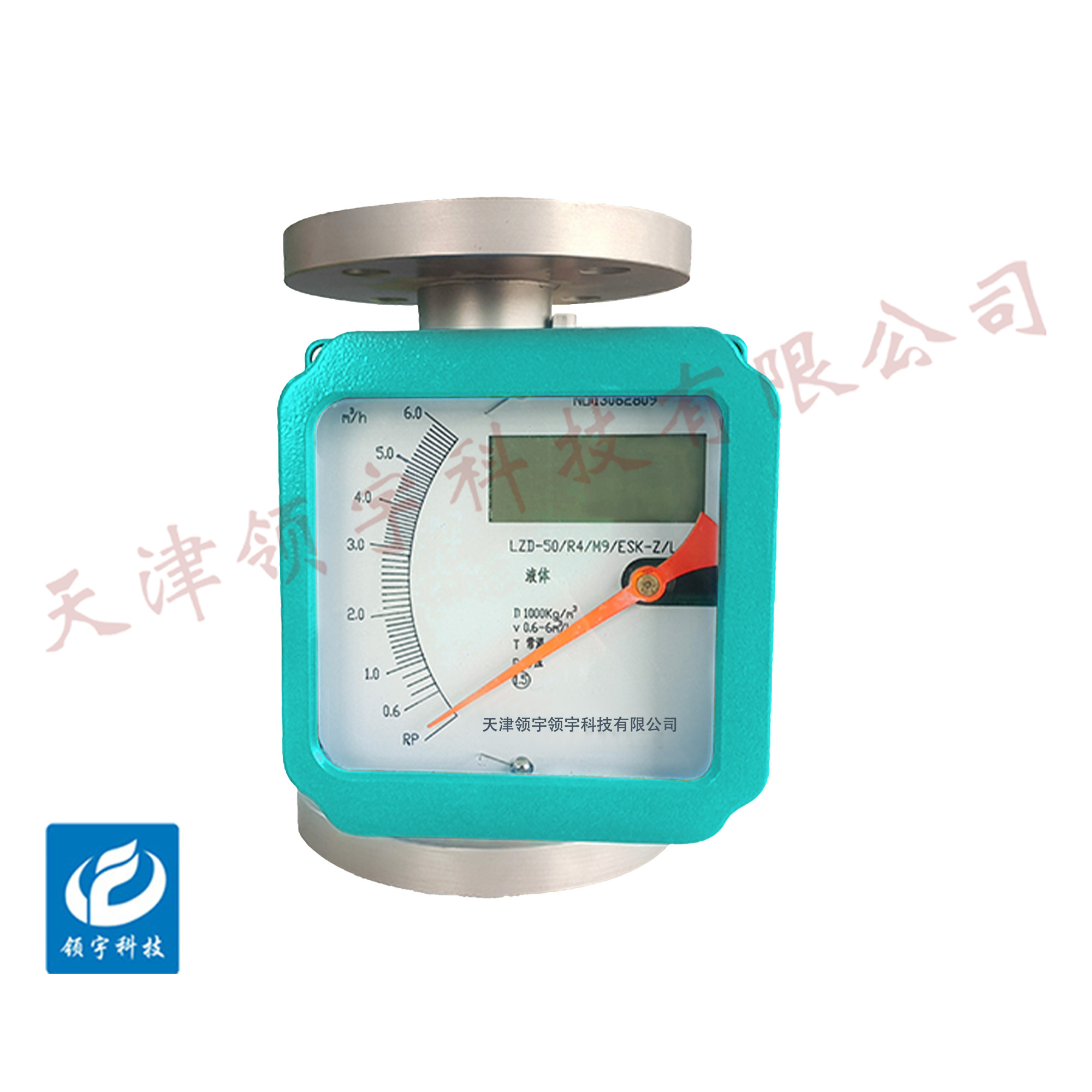

Product display

LF17-...1 Series Metal Rotameters

The LF17-... series of metal rotor flowmeters employs the variable-area measurement principle and is designed for continuous measurement of volumetric flow rates of liquids and gases in closed pipelines. These metal-tube float flowmeters feature a robust and reliable structure, a wide operating temperature range, high accuracy, and an affordable price, making them suitable for a variety of flow measurement applications. This series offers a smart on-site indication option and comes in three installation configurations: bottom-in-top-out, left-in-right-out, and bottom-in-side-out. They can be widely used in sectors such as national defense, chemical industry, petroleum metallurgy, power generation, environmental protection, pharmaceuticals, and light industries for measuring liquid and gas flow rates. Key features of this product include:

● Resistant to Harsh Operating Conditions: Its metal construction (such as stainless steel) endows it with high-pressure and high-temperature resistance, making it suitable for corrosive or high-temperature media in industrial sectors like petroleum and chemical processing.

● Ideal for small to medium flow rates: Based on the float-up principle, it offers higher measurement accuracy for low flow velocities and media flowing through small-to-medium pipe diameters (typically DN15–DN200), making it especially suitable for scenarios with unstable flow conditions.

● Easy installation and maintenance: Can be installed vertically without needing to reserve long straight pipe sections like turbine flowmeters; features a simple design with no complex moving parts inside, resulting in low maintenance costs.

● Intuitive readings: Traditional models feature a transparent cone tube with scale markings, allowing direct observation of the float position to measure flow rate; the smart version, meanwhile, supports digital display, making data acquisition even more convenient.

View Details +

● Resistant to Harsh Operating Conditions: Its metal construction (such as stainless steel) endows it with high-pressure and high-temperature resistance, making it suitable for corrosive or high-temperature media in industrial sectors like petroleum and chemical processing.

● Ideal for small to medium flow rates: Based on the float-up principle, it offers higher measurement accuracy for low flow velocities and media flowing through small-to-medium pipe diameters (typically DN15–DN200), making it especially suitable for scenarios with unstable flow conditions.

● Easy installation and maintenance: Can be installed vertically without needing to reserve long straight pipe sections like turbine flowmeters; features a simple design with no complex moving parts inside, resulting in low maintenance costs.

● Intuitive readings: Traditional models feature a transparent cone tube with scale markings, allowing direct observation of the float position to measure flow rate; the smart version, meanwhile, supports digital display, making data acquisition even more convenient.

LF17-...W Series Hygienic Metal Rotameter

The LF17-... series of metal rotor flowmeters employs the variable-area measurement principle and is designed for continuous measurement of volumetric flow rates of liquids and gases in closed pipelines. These metal-tube float flowmeters feature a robust and reliable design, a wide operating temperature range, high accuracy, and an affordable price, making them suitable for flow measurement in a variety of applications. This series offers a smart on-site indication option and comes in three installation configurations: bottom-in-top-out, left-in-right-out, and bottom-in-side-out. They can be widely used in departments such as national defense, chemical industry, petroleum metallurgy, power generation, environmental protection, pharmaceuticals, and light industries for measuring liquid and gas flow rates. Key features of this product include:

● Resistant to Harsh Operating Conditions: Its metal construction—such as stainless steel—endows it with high-pressure and high-temperature resistance, making it suitable for corrosive or high-temperature media in industrial fields like petroleum and chemical processing.

● Ideal for small to medium flow rates: Based on the float-up principle, it offers higher measurement accuracy for low flow velocities and media flowing through small to medium pipe diameters (typically DN15–DN200), making it especially suitable for applications with unstable flow conditions.

● Easy installation and maintenance: Can be installed vertically without needing to reserve long straight pipe sections like turbine flowmeters; features a simple design with no complex moving parts inside, resulting in low maintenance costs.

● Intuitive readings: Traditional models feature a transparent cone tube with scale markings, allowing direct observation of the float position to measure flow rate; smart models, on the other hand, offer digital displays for even more convenient data acquisition.

View Details +

● Resistant to Harsh Operating Conditions: Its metal construction—such as stainless steel—endows it with high-pressure and high-temperature resistance, making it suitable for corrosive or high-temperature media in industrial fields like petroleum and chemical processing.

● Ideal for small to medium flow rates: Based on the float-up principle, it offers higher measurement accuracy for low flow velocities and media flowing through small to medium pipe diameters (typically DN15–DN200), making it especially suitable for applications with unstable flow conditions.

● Easy installation and maintenance: Can be installed vertically without needing to reserve long straight pipe sections like turbine flowmeters; features a simple design with no complex moving parts inside, resulting in low maintenance costs.

● Intuitive readings: Traditional models feature a transparent cone tube with scale markings, allowing direct observation of the float position to measure flow rate; smart models, on the other hand, offer digital displays for even more convenient data acquisition.

LF17-...4 Series Metal Rotameters

The LF17-... series of metal rotor flowmeters employs the variable-area measurement principle and is designed for continuous measurement of volumetric flow rates of liquids and gases in closed pipelines. These metal-tube float flowmeters feature a robust and reliable design, a wide operating temperature range, high accuracy, and an affordable price, making them suitable for flow measurement in various applications. This series comes in a smart on-site indicator version, available in three installation configurations: bottom-in-top-out, left-in-right-out, and bottom-in-side-out. They can be widely used in departments such as national defense, chemical industry, petroleum metallurgy, power generation, environmental protection, pharmaceuticals, and light industries for measuring liquid and gas flow rates. Key features of this product include:

● Resistant to Harsh Operating Conditions: Its metal construction—such as stainless steel—endows it with high-pressure and high-temperature resistance, making it suitable for corrosive or high-temperature media in industrial sectors like petroleum and chemical processing.

● Ideal for small to medium flow rates: Based on the float-up principle, it offers higher measurement accuracy for low flow velocities and media flowing through small to medium pipe diameters (typically DN15–DN200), making it especially suitable for applications with unstable flow conditions.

● Easy installation and maintenance: Can be installed vertically without needing to reserve long straight pipe sections like turbine flowmeters; features a simple design with no complex moving parts inside, resulting in low maintenance costs.

● Intuitive readings: Traditional models feature a transparent conical tube with scale markings, allowing direct observation of the float position to measure flow rate; the smart version, meanwhile, supports digital display, making data acquisition even more convenient.

View Details +

● Resistant to Harsh Operating Conditions: Its metal construction—such as stainless steel—endows it with high-pressure and high-temperature resistance, making it suitable for corrosive or high-temperature media in industrial sectors like petroleum and chemical processing.

● Ideal for small to medium flow rates: Based on the float-up principle, it offers higher measurement accuracy for low flow velocities and media flowing through small to medium pipe diameters (typically DN15–DN200), making it especially suitable for applications with unstable flow conditions.

● Easy installation and maintenance: Can be installed vertically without needing to reserve long straight pipe sections like turbine flowmeters; features a simple design with no complex moving parts inside, resulting in low maintenance costs.

● Intuitive readings: Traditional models feature a transparent conical tube with scale markings, allowing direct observation of the float position to measure flow rate; the smart version, meanwhile, supports digital display, making data acquisition even more convenient.

Tianjin Ling Yu Technology Co., Ltd.

Operator:86-22-58554679

Fax: 022-58285528

Manager Ding: 86-18902041592

WhatsApp:8618902041592

Complaint Hotline:86-15822286986

Factory Address: No.5 Yingbin Road, Xiqing District, Tianjin

E-mail:sales@lingyukeji.com

Purchasing Department E-mail:lykj_tj@163.com

Business License

WhatsApp Scan

Copyright©2022 Tianjin Ling Yu Technology Co., Ltd