Product display

LF-19P Series Nozzle Flow Meters

The LF-19P series nozzle flowmeter is a differential-pressure type flow measurement instrument based on the throttling principle. Its core component is a nozzle with a specially designed curved profile. By installing the nozzle directly into the pipeline, the flowing fluid creates a pressure difference as it passes through, allowing the flow rate to be accurately calculated. As the fluid flows through the nozzle, it gradually contracts at the inlet, causing the flow velocity to increase while the static pressure decreases. At the throat section immediately downstream of the nozzle outlet, the flow velocity reaches its maximum, and the static pressure drops to its lowest point. By measuring the pressure difference before and after the nozzle—and combining this data with fluid properties such as density and temperature—it becomes possible to determine the fluid’s instantaneous and cumulative flow rates using Bernoulli’s equation. The streamlined design of the nozzle minimizes turbulence at the throttling point, making the device less sensitive to solid particles in the medium and significantly enhancing its resistance to clogging. This makes it particularly well-suited for measuring fluids that are dirty or contain minor impurities. The product is widely used in industries such as power generation, chemical processing, and petroleum, especially for applications involving steam, gases, and high-viscosity liquids. Key features of this product include:

●Low pressure loss and excellent energy-saving performance: Compared to traditional orifice plates, the nozzle's streamlined design effectively minimizes vortex formation.

● Anti-clogging and wear-resistant with a robust structure: The internal design features no complex components, making the throttling edges highly resistant to wear. Its design prevents debris buildup, making it ideal for handling dirty media containing small particles—and ensuring an exceptionally long service life.

● High measurement accuracy and stable performance: Measurement accuracy typically ranges from ±0.5% to ±2% of full scale, with minimal impact from fluid viscosity and flow velocity fluctuations, ensuring consistent and reliable measurements across a wide flow range.

● Wide range of applicable conditions: It can measure various media such as liquids, gases, and steam, making it particularly suitable for high-temperature, high-pressure, and high-flow applications. It is widely used in industries like power generation, chemical processing, and petroleum.

View Details +

●Low pressure loss and excellent energy-saving performance: Compared to traditional orifice plates, the nozzle's streamlined design effectively minimizes vortex formation.

● Anti-clogging and wear-resistant with a robust structure: The internal design features no complex components, making the throttling edges highly resistant to wear. Its design prevents debris buildup, making it ideal for handling dirty media containing small particles—and ensuring an exceptionally long service life.

● High measurement accuracy and stable performance: Measurement accuracy typically ranges from ±0.5% to ±2% of full scale, with minimal impact from fluid viscosity and flow velocity fluctuations, ensuring consistent and reliable measurements across a wide flow range.

● Wide range of applicable conditions: It can measure various media such as liquids, gases, and steam, making it particularly suitable for high-temperature, high-pressure, and high-flow applications. It is widely used in industries like power generation, chemical processing, and petroleum.

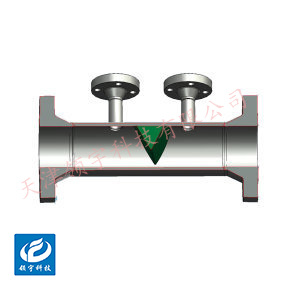

The LF-19Q Venturi flowmeter is a differential-pressure-type flow measurement instrument designed based on Bernoulli's equation and the principle of fluid continuity. Its core structure consists of three main sections: an inlet contraction section, a central throat, and an outlet diffusion section. Due to its simple design and low energy consumption, it is widely used in industrial fluid measurement applications. This product features the following characteristics:

● Minimal pressure loss and excellent energy efficiency: The unique "contraction-throat-expansion" structure recovers approximately 90% of the static pressure energy.

● Anti-clogging and wear-resistant with strong adaptability: The inner wall features a smooth surface free of sharp edges or constricted dead zones, making it highly resistant to impurity buildup (such as particles in wastewater or deposits in steam). This design ensures stable performance even under challenging conditions, including liquids containing minor impurities, high-temperature gases like steam, and corrosive media such as chemical solutions.

● Stable measurement with reliable accuracy: Measurement accuracy typically ranges from ±1% to ±2.5% of full scale (FS), and is minimally affected by fluctuations in fluid flow velocity or changes in medium viscosity. It ensures consistent, stable readings across a wide range of flow rates—from small to large (pipe diameters DN50 to DN2000).

● Flexible installation requirements: Only a straight pipe section of 5–10 times the pipe diameter upstream and 3–5 times downstream is needed—significantly less than the requirement for turbine flowmeters (10D upstream, 5D downstream)—making it more adaptable to limited installation spaces, especially ideal for scenarios with compact pipe layouts.

View Details +

● Minimal pressure loss and excellent energy efficiency: The unique "contraction-throat-expansion" structure recovers approximately 90% of the static pressure energy.

● Anti-clogging and wear-resistant with strong adaptability: The inner wall features a smooth surface free of sharp edges or constricted dead zones, making it highly resistant to impurity buildup (such as particles in wastewater or deposits in steam). This design ensures stable performance even under challenging conditions, including liquids containing minor impurities, high-temperature gases like steam, and corrosive media such as chemical solutions.

● Stable measurement with reliable accuracy: Measurement accuracy typically ranges from ±1% to ±2.5% of full scale (FS), and is minimally affected by fluctuations in fluid flow velocity or changes in medium viscosity. It ensures consistent, stable readings across a wide range of flow rates—from small to large (pipe diameters DN50 to DN2000).

● Flexible installation requirements: Only a straight pipe section of 5–10 times the pipe diameter upstream and 3–5 times downstream is needed—significantly less than the requirement for turbine flowmeters (10D upstream, 5D downstream)—making it more adaptable to limited installation spaces, especially ideal for scenarios with compact pipe layouts.

LF19B1 Series Balanced Orifice Flowmeter

The LF19B1 series balanced orifice plate flowmeter is a typical differential-pressure flowmeter, designed for use in conjunction with transmitters and display instruments (or control units). It enables precise measurement of fluid flow and is widely adopted across various industrial sectors due to its simple structure, convenient installation, and reliable operational performance.

Orifice plate flowmeters boast a long history of practical application, backed by extensive experimental data. Their design and manufacturing processes have already been standardized, eliminating the need for actual-flow calibration. Moreover, these flowmeters can handle a wide variety of measured media, accommodate diverse pipe diameters, and operate effectively at temperatures as high as 550°C—and even withstand pressures up to 32 MPa. As such, they remain one of the primary instruments used for flow measurement in industrial automation and control processes.

This product features the following key characteristics:

● The structure is easy to replicate, simple yet sturdy, with stable and reliable performance, and at an affordable price.

● Widely applicable, covering single-phase fluids (liquid, gas, steam), as well as partially immiscible flows. Products are available for pipe diameters and operating conditions—such as temperature and pressure—commonly encountered in industrial processes. Moreover, throttling devices, differential pressure transmitters, and display instruments can be manufactured separately by different suppliers, making large-scale production more convenient.

●The annular chamber and drilled holes enhance measurement accuracy while reducing the minimum required straight pipe length for installation.

● In addition to its online, dynamic full-compensation function, the intelligent orifice flowmeter also features self-diagnosis and automatic range setting.

View Details +

● The structure is easy to replicate, simple yet sturdy, with stable and reliable performance, and at an affordable price.

● Widely applicable, covering single-phase fluids (liquid, gas, steam), as well as partially immiscible flows. Products are available for pipe diameters and operating conditions—such as temperature and pressure—commonly encountered in industrial processes. Moreover, throttling devices, differential pressure transmitters, and display instruments can be manufactured separately by different suppliers, making large-scale production more convenient.

●The annular chamber and drilled holes enhance measurement accuracy while reducing the minimum required straight pipe length for installation.

● In addition to its online, dynamic full-compensation function, the intelligent orifice flowmeter also features self-diagnosis and automatic range setting.

LF-19B2 Series Ball-Type Flow Meters

The LF-19B2 series of vane-type flowmeters builds upon the traditional isolated-diaphragm target flowmeter by integrating a new strain sensor into the target design. At the same time, it leverages the latest digital and microelectronic technologies to process the detected sensor signals into a 4–20mA output proportional to the flow rate. The instrument also features dual-row large LCD displays that simultaneously show both instantaneous and cumulative flow rates, significantly enhancing both the structural design and performance of conventional target flowmeters. This model is particularly well-suited for measuring complex fluids with high viscosity, low Reynolds numbers, or those containing suspended particles. Key features of this product include:

● High-temperature and high-pressure resistance: Ranges from -80°C to +200°C, with pressure capacity up to 10 MPa

● Suitable for various diameters: φ15–φ1500mm

● Suitable for measuring highly viscous media containing sediment and sand

● Multiple installation options available: clamp-type, flange-type, threaded-type, insertion-type, detachable insertion-type, sanitary-type, and integrated/segmented designs.

View Details +

● High-temperature and high-pressure resistance: Ranges from -80°C to +200°C, with pressure capacity up to 10 MPa

● Suitable for various diameters: φ15–φ1500mm

● Suitable for measuring highly viscous media containing sediment and sand

● Multiple installation options available: clamp-type, flange-type, threaded-type, insertion-type, detachable insertion-type, sanitary-type, and integrated/segmented designs.

LF-19F Series Orifice Flow Meters

The LF-19F series orifice plate flowmeter is a typical differential-pressure flowmeter, designed for use with transmitters and display instruments (or control units). It enables precise measurement of fluid flow and is widely adopted across various industrial sectors due to its simple structure, convenient installation, and reliable operational performance. With a long history of practical application and abundant experimental data, the design and manufacturing of this flowmeter have been standardized, eliminating the need for actual-flow calibration. It supports a wide range of measured media, covers an extensive spectrum of pipe diameters, and can handle measurement temperatures up to 550°C as well as pressures as high as 32 MPa. As such, it remains one of the primary instruments used for flow measurement in industrial automation and control processes. This product boasts the following key features:

● The structure is easy to replicate, simple yet sturdy, with stable and reliable performance, and at an affordable price.

● Widely applicable, covering single-phase fluids (liquid, gas, steam), as well as partially miscible flows. Products are available for pipe diameters and operating conditions—such as temperature and pressure—commonly encountered in industrial processes. Moreover, throttling devices, differential pressure transmitters, and display instruments can be manufactured separately by different suppliers, making it easier to achieve large-scale production.

●The annular chamber and drilled holes enhance measurement accuracy while reducing the minimum required straight pipe length for installation.

● In addition to its online, dynamic full-compensation function, the intelligent orifice flowmeter also features self-diagnosis and automatic range setting.

View Details +

● The structure is easy to replicate, simple yet sturdy, with stable and reliable performance, and at an affordable price.

● Widely applicable, covering single-phase fluids (liquid, gas, steam), as well as partially miscible flows. Products are available for pipe diameters and operating conditions—such as temperature and pressure—commonly encountered in industrial processes. Moreover, throttling devices, differential pressure transmitters, and display instruments can be manufactured separately by different suppliers, making it easier to achieve large-scale production.

●The annular chamber and drilled holes enhance measurement accuracy while reducing the minimum required straight pipe length for installation.

● In addition to its online, dynamic full-compensation function, the intelligent orifice flowmeter also features self-diagnosis and automatic range setting.

The LF-19X wedge flowmeter is a flow measurement instrument designed based on the differential pressure principle. Its core component is a V-shaped or wedge-shaped throttling element, primarily used to address the challenges of measuring flow rates for "dirty fluids" such as high-viscosity liquids, fluids containing solid particles, and substances prone to scaling. This makes it an ideal solution that overcomes the common issue of clogging found in conventional differential-pressure flowmeters like standard orifice plates and Venturi tubes. The product features the following characteristics:

● Wide applicability: Particularly adept at measuring high-viscosity or impurity-laden fluids such as crude oil, asphalt, pulp, and mud; also suitable for use with conventional gases and liquids.

● Strong anti-clogging capability: The wedge-shaped throttling element features no sharp dead corners between itself and the pipeline, preventing solid particles or viscous media in the fluid from easily accumulating, thus extending the maintenance cycle.

●Low installation requirements: The length of the straight pipe sections required upstream and downstream is significantly shorter than that for standard orifice plates (typically just 5D upstream and 2D downstream, where D represents the pipe diameter), saving valuable installation space.

View Details +

● Wide applicability: Particularly adept at measuring high-viscosity or impurity-laden fluids such as crude oil, asphalt, pulp, and mud; also suitable for use with conventional gases and liquids.

● Strong anti-clogging capability: The wedge-shaped throttling element features no sharp dead corners between itself and the pipeline, preventing solid particles or viscous media in the fluid from easily accumulating, thus extending the maintenance cycle.

●Low installation requirements: The length of the straight pipe sections required upstream and downstream is significantly shorter than that for standard orifice plates (typically just 5D upstream and 2D downstream, where D represents the pipe diameter), saving valuable installation space.

Tianjin Ling Yu Technology Co., Ltd.

Operator:86-22-58554679

Fax: 022-58285528

Manager Ding: 86-18902041592

WhatsApp:8618902041592

Complaint Hotline:86-15822286986

Factory Address: No.5 Yingbin Road, Xiqing District, Tianjin

E-mail:sales@lingyukeji.com

Purchasing Department E-mail:lykj_tj@163.com

Business License

WhatsApp Scan

Copyright©2022 Tianjin Ling Yu Technology Co., Ltd