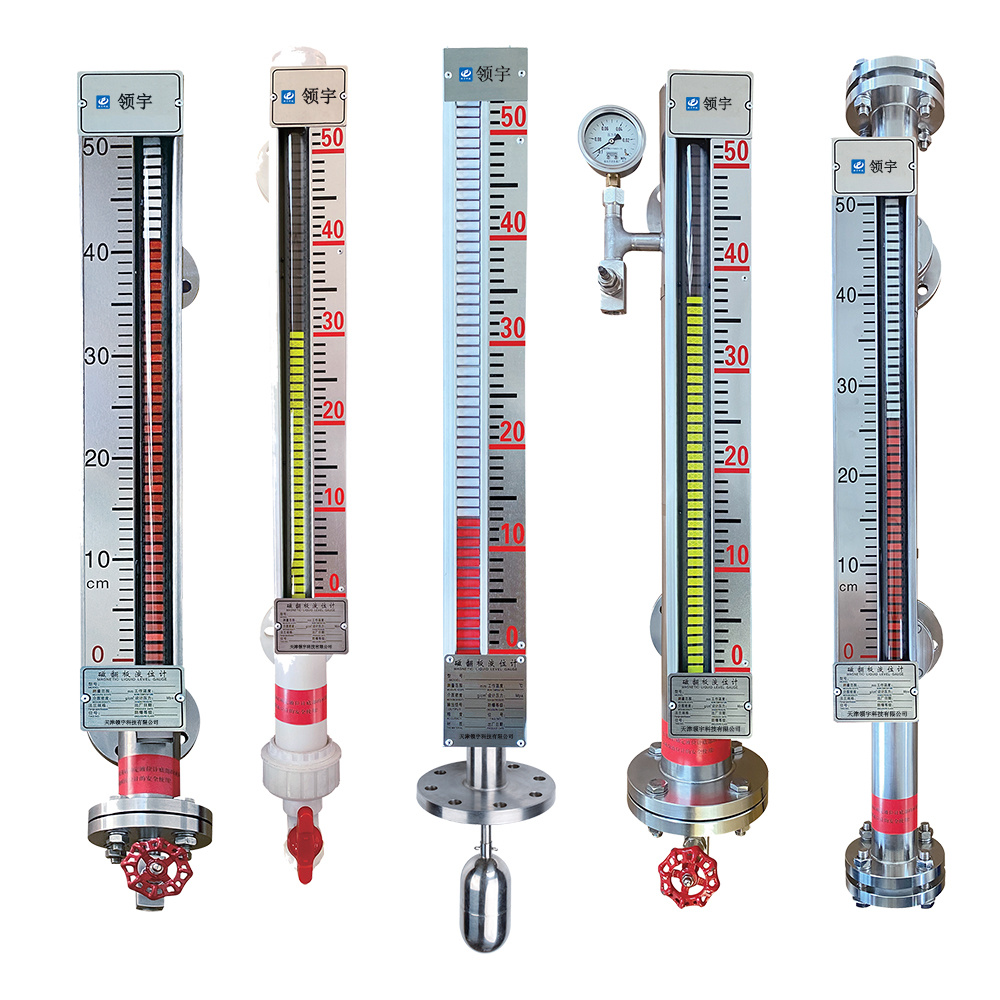

Product display

LRB Series Magnetic Flip-Plate Level Gauge

● Level indication requires no power

● Optional installation of electric actuators and limit switches

●Mechanical interlock design to prevent random flipping

● Clear instructions, resistant to oxidation, volatilization, and corrosion

● Suitable for high-temperature and high-pressure applications

● Diverse types, with optional materials

Key words:

Classification:

Download information:

Product Description

Product Overview Product overview

The magnetic flip-plate level gauge is suitable for liquid level measurement in open or pressurized vessels. Thanks to its unique design, this instrument is particularly well-suited for use with corrosive, hazardous, or flammable media—and in harsh environmental conditions. The on-site liquid level indication does not require a power supply. Additionally, this gauge can optionally be equipped, either simultaneously or separately, with an electric remote transmission system and limit switches. It is widely used across industries such as chemical processing, metallurgy, water resources, pharmaceuticals, and petroleum.

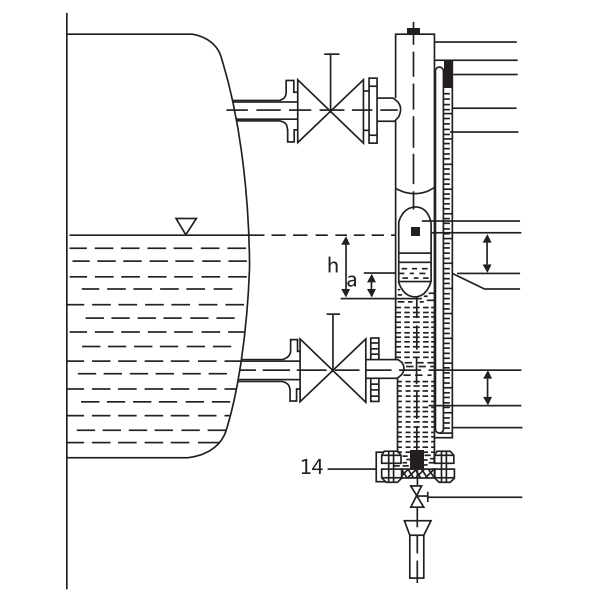

Product Principle THE PRODUCT PRINCIPLE

The measurement principle of the magnetic flip-plate level gauge is based on the bypass pipe-type liquid measurement method. The measuring tube, connected as a bypass container to the main vessel, ensures that all conditions inside the measuring tube mirror those within the vessel itself. A permanent magnet system is installed inside the float, enabling the measured value to be transmitted to the indicator via magnetic coupling. The indicator features a linear scale that moves in response to changes in the liquid level, with the magnet system inside the float driving the magnetic flip plates—or the float itself—to accurately indicate the corresponding liquid level within the container.

Product Structure Product structure

The magnetic flip plate consists of three parts: the measuring tube, the indicator, and the float.

Measurement tube measuring tube

1. Multiple installation methods and process connection types: flange connections, threaded connections, clamp connections, welding, and more.

2. The measuring tube is connected to the process via a cold-drawn extrusion outlet, ensuring more reliable float operation while eliminating welding-induced deformation.

3. Available in a variety of materials including 304L, 304SS, 316L, PP, UPVC, PPH, stainless steel-lined PTFE, Hastelloy alloy, Monel, titanium, zirconium, and more.

Float floats

The float is the core component of the magnetic flip plate, featuring a built-in 360° ring magnet that interacts with the indicator, transmitter, and alarm switch to achieve mechanical automation.

Float test pressure = 1.5 × Float's maximum allowable working pressure at 20°C,

Temperature range: -150~500℃

Pressure resistance: -0.1 to 42 MPa

Indicator Indicator

The indicator consists of a scale, magnetic beads, mounting profiles, and clamps, featuring a clamp-based installation for easy replacement and offering a variety of types and material options.

Stainless Steel Ruler

Vacuum glass tube encapsulation

The magnetic flip cards are made from special materials that withstand high and low temperatures.

Magnetic flip-plate mechanical interlock design prevents random flipping.

Different engineering unit instructions

Clear instructions, anti-oxidation, cavitation resistance, corrosion resistance, and dust protection

Selection parameters Selection

Instrument selection requires the following parameters—please make your choice based on the operating conditions. A product that performs well is often the result of selecting the right one, so proceed with caution.

1 Material: 304SS / 304L / 316L / PP / UPVC / PPH / Stainless Steel Lined with PTFE, Hastelloy, Monel, Zirconium, and other materials

2 Measurement range: 0.2–20 m (large ranges available upon negotiation)

3 Installation methods: Side-by-side installation, top installation, side-in-top-out, bottom-in-top-out, bottom-in-side-out

4 Connection Methods: Flange, Threaded, Clamp, and Welding—DN6 to DN250

5 Temperature range: -190 to 500°C,

6 Pressure Range: -0.1 to 32 MPa

7 Density range: ≥0.4 g/cm³

8 Transmitters: Reed Switch, Magnetoresistive Chip, Magnetostrictive

9 Switches: Magnetic Latching Up/Down Switches, Transfer Switches, and Audio-Visual Alarms

Related Products

Product inquiry

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!

Tianjin Ling Yu Technology Co., Ltd.

Operator:86-22-58554679

Fax: 022-58285528

Manager Ding: 86-18902041592

WhatsApp:8618902041592

Complaint Hotline:86-15822286986

Factory Address: No.5 Yingbin Road, Xiqing District, Tianjin

E-mail:sales@lingyukeji.com

Purchasing Department E-mail:lykj_tj@163.com

WhatsApp Scan

Copyright©2022 Tianjin Ling Yu Technology Co., Ltd