Product display

LRF Series Float Level Gauge

● Suitable for sealed tanks

● Suitable for level measurement in a variety of media

● Chemicals, petrochemicals, natural gas, offshore platforms, shipbuilding industry, power generation equipment, machinery manufacturing, and power plants, among other sectors

● Industrial water and drinking water treatment, food and beverage industry, pharmaceuticals

Key words:

Classification:

Download information:

Product Description

Product Overview Product overview

This series of float level gauges offers continuous liquid level measurement unaffected by physical and chemical properties such as foam, conductivity, dielectric constant, pressure, vacuum, steam, condensation, air bubbles, boiling effects, and density variations. The HART® interface enables simultaneous measurement of both interface and overall liquid levels. The displayed level reading can be directly proportional to either height or volume. Process connections, guide tubes, and floats are available in a variety of materials, including stainless steel, titanium, and various types of plastic.

Product Principle THE PRODUCT PRINCIPLE

The system employs reed resistor chain technology and measures liquid levels based on the principle of magnetic conduction. The magnetic field lines from the magnet embedded within the float pass through the guide tube, inducing the reed switches and resistor chain inside. This interaction generates a voltage output—via a three-wire voltage divider—that is directly proportional to the liquid level. Thanks to the tightly packed arrangement of the reed switches and resistor chain, the voltage changes nearly continuously.

Performance metrics TECHNICAL PARAMETERS

Applicable media: Level measurement for various media

Applications: Open tanks, sealed containers, and measurement of liquids under high pressure

Explosion-proof certification: Exd IIC T6 Gb

Measurement range: 0–5 m

Measurement accuracy: 0.5% FS

Process temperature: (-200 to 400)°C

Process pressure: (-0.1 to 40) MPa

Signal output: (4–20) mA/HART

On-site display: Four LCDs, programmable

Power Supply: Two-wire system (DC 24V) / Four-wire system (DC 24V / AC 220V)

Shell materials: Aluminum single-cavity / Aluminum double-cavity / Plastic / Stainless steel single-cavity

Process connection: Threaded/Flanged (optional)

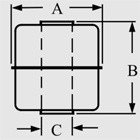

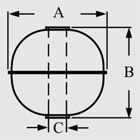

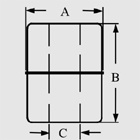

Float Ball Specifications Specifications

| Float ball | Model | Dimensions A × B × C (mm) | Material | Density g/cm³ | Temperature resistance ℃ | High-pressure bar |

|

S1 | 28 × 28 × 9.5 | SUS316L | 0.8 | 200 | 10 |

| S2 | 38 × 26.5 × 9.5 | SUS316L | 0.7 | 200 | 12 | |

| S3 | 45 × 55 × 15 | SUS316L | 0.65 | 200 | 15 | |

|

S4 | 52 × 52 × 15 | SUS316L | 0.55 | 200 | 30 |

| S5 | 75 * 75 * 23 | SUS304 | 0.7 | 200 | 64 | |

|

P1 | 26 × 18 × 10 | PP | 0.8 | 80 | 4 |

| P2 | 48 * 50 * 20 | PP | 0.8 | 80 | 4 | |

| F1 | 55 × 70 × 23 | PVDF | 0.9 | 150 | 3 |

Previous Page

Next Page

Previous Page

Next Page

Related Products

Product inquiry

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!

Tianjin Ling Yu Technology Co., Ltd.

Operator:86-22-58554679

Fax: 022-58285528

Manager Ding: 86-18902041592

WhatsApp:8618902041592

Complaint Hotline:86-15822286986

Factory Address: No.5 Yingbin Road, Xiqing District, Tianjin

E-mail:sales@lingyukeji.com

Purchasing Department E-mail:lykj_tj@163.com

WhatsApp Scan

Copyright©2022 Tianjin Ling Yu Technology Co., Ltd