Product display

LR-S2 Series Float Level Switch

● Suitable for sealed tanks

● The reed switch contact material is rhodium (with a surface layer of rhodium oxide), offering a contact life of up to 2 million cycles.

● The special treatment of the reed switch enables it to operate normally even at high temperatures of 200°C.

● Multiple control points can be implemented, and the position of each control point can be customized according to customer needs.

● All the outgoing wires from the switches are concentrated inside the junction box, making installation simple and convenient while reducing wiring costs.

● The junction box has an IP65 or higher protection rating and can be configured with intrinsically safe or flameproof types as needed.

● Overall performance is reliable. Materials available include SUS304, SUS316L, PP, PVDF, PTFE, and more.

● Length can be custom-made to any size (Lmax ≤ 5m)

Key words:

Classification:

Download information:

Product Description

Product Overview Product overview

This series of float-type level switches is designed to detect one or more critical position points in liquid levels. They operate unaffected by factors such as foam, conductivity, dielectric constant, pressure, vacuum, temperature, steam, condensation, boiling effects, or even vibration—making them suitable for nearly all liquid media. The switch features non-contact operation, zero wear, and requires no external power source. With a straightforward operating principle that has been thoroughly tested over time, these switches are ideal for a wide range of applications, from general industrial uses to sophisticated process equipment. They are widely employed across industries including chemical processing, metallurgy, water management, pharmaceuticals, and petroleum.

Product Principle THE PRODUCT PRINCIPLE

Typically, a sealed non-magnetic metal or plastic tube is fitted with a reed switch at the desired location. Inside this tube, a hollow float—containing a ring-shaped magnet—is fixed along the rod’s diameter, precisely aligned with the reed switch. Since the float’s specific gravity is lower than that of the liquid, it floats up and down within a defined range as the liquid level changes. The magnet inside the float then attracts the reed switch, causing it to close and triggering the switching action, which ultimately controls the liquid level. Note that "normally open" and "normally closed" refer to the state of the switch when no liquid is present.

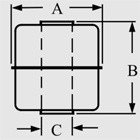

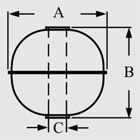

Float Ball Specifications Specifications

| Float ball | Model | Dimensions A × B × C (mm) | Material | Density g/cm³ | Temperature resistance ℃ | High-pressure bar |

|

S1 | 28 × 28 × 9.5 | SUS316L | 0.8 | 200 | 10 |

| S2 | 38 * 26.5 * 9.5 | SUS316L | 0.7 | 200 | 12 | |

| S3 | 45 × 55 × 15 | SUS316L | 0.65 | 200 | 15 | |

|

S4 | 52 × 52 × 15 | SUS316L | 0.55 | 200 | 30 |

| S5 | 75 * 75 * 23 | SUS304 | 0.7 | 200 | 64 | |

|

P1 | 26 × 18 × 10 | PP | 0.8 | 80 | 4 |

| P2 | 48 * 50 * 20 | PP | 0.8 | 80 | 4 | |

| F1 | 55 × 70 × 23 | PVDF | 0.9 | 150 | 3 |

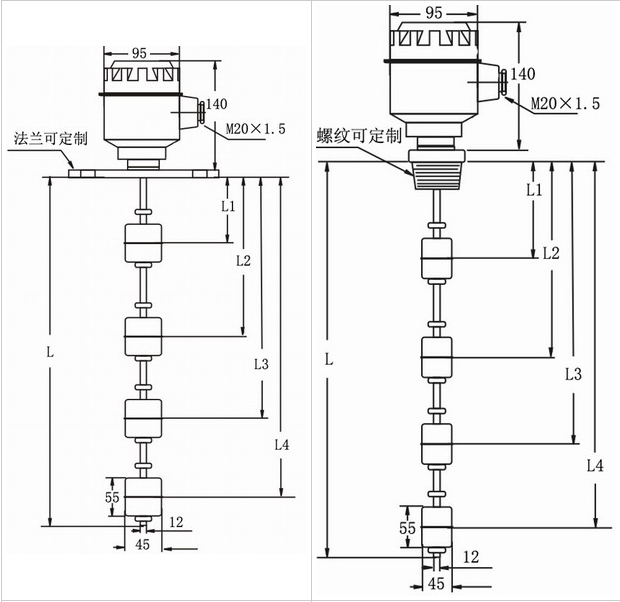

External dimensions Size

Selection Assistance Selection

When selecting a float level switch, the following parameters are required: 1. The pressure, temperature, and density of the medium; 2. Whether to install it on the side or at the top of the tank; 3. High-level and low-level alarms—specify the alarm positions; 4. Number of alarm points; 5. Opening size—use this to determine the appropriate float size (also consider the medium’s density for a comprehensive decision); 6. Connection type—choose between flange or threaded fittings; 7. Consider viscosity and corrosiveness of the medium.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Product inquiry

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!

Tianjin Ling Yu Technology Co., Ltd.

Operator:86-22-58554679

Fax: 022-58285528

Manager Ding: 86-18902041592

WhatsApp:8618902041592

Complaint Hotline:86-15822286986

Factory Address: No.5 Yingbin Road, Xiqing District, Tianjin

E-mail:sales@lingyukeji.com

Purchasing Department E-mail:lykj_tj@163.com

WhatsApp Scan

Copyright©2022 Tianjin Ling Yu Technology Co., Ltd